OSHA Paint Storage Regulations

Like with any dangerous chemicals, OSHA has developed numerous enforceable regulations related to proper paint storage. These regulations exist to prevent sudden fires and injury through toxicity exposure. Most commercial and industrial coatings and paint fall under two categories: oil-based and water-based. Because oil based paints contain high levels of solvents per volume, they are classified as flammable liquids. OSHA 1926.152 stipulates that “no more than 60 gallons of Category 1, 2 and/or 3 flammable liquids or 120 gallons of Category 4 flammable liquids shall be stored in any one storage cabinet.” Federal regulations also require that inside storage lockers should be constructed of fire-resistant rated materials for proper paint storage. U.S. Hazmat Rentals line of steel rated paint storage buildings can meet stringent OSHA paint storage regulations.

Why is Paint Storage Regulated?

While seemingly inert in application, all types of paint can be inherently dangerous if mishandled or improperly stored. Oil based paints, for example, contain a large amount of hydrocarbons, which are prone to sudden combustion and can cause serious toxicity through human exposure and inhalation. Although latex paints are deemed less harmful than traditional oil-based counterparts, exposure to these chemicals can cause mild irritation to the skin and mouth. Most latex paints are made from plastic polymer known as acrylic resin. This type of material can become particularly dangerous to human exposure as it may contain trace amounts of ethyl acrylate, which is a known carcinogen. Our paint storage buildings can be retrofitted with metal partitioned walls and unique compartmentalization options that can prevent indirect human exposure to these dangerous chemicals.

Environmental contamination and pollution can also occur if paints are not properly stored in a steel-welded storage locker that is outfitted with an innovative spill sump containment system. Regardless of use or composition, OSHA requires fire-rated protection for large quantities of oil-based and water-based paints that fall within a flash point of 73 F to 140 degrees F. Failure to abide by OSHA paint storage regulations can subject your company to insurmountable civil penalties and a negative reputation that can forever tarnish a business’s legacy.

Proper paint storage and OSHA compliance help manage safe storage and handling of paints and chemicals components found in paints like:

- Paint

- varnishes

- solvents

- thinners

- acetone (C3H6O)

- alcohol

- Paint pigments

- mineral spirits

- Oil-based paints

- Water-based paints

- Acrylics paints

- Latex (PVA)

- Acrylics polymers

- Alkyd polymers

- Epoxy polymers

- Enamel paints

- Phenolic resins

- Vinyl paints [polyvinyl acetate or polyvinyl chloride]

- Binders

- Resins

- Xylene (C8H10 )Retarder

- Extender

- Pigments

- Additives

Is storing paint a fire hazard?

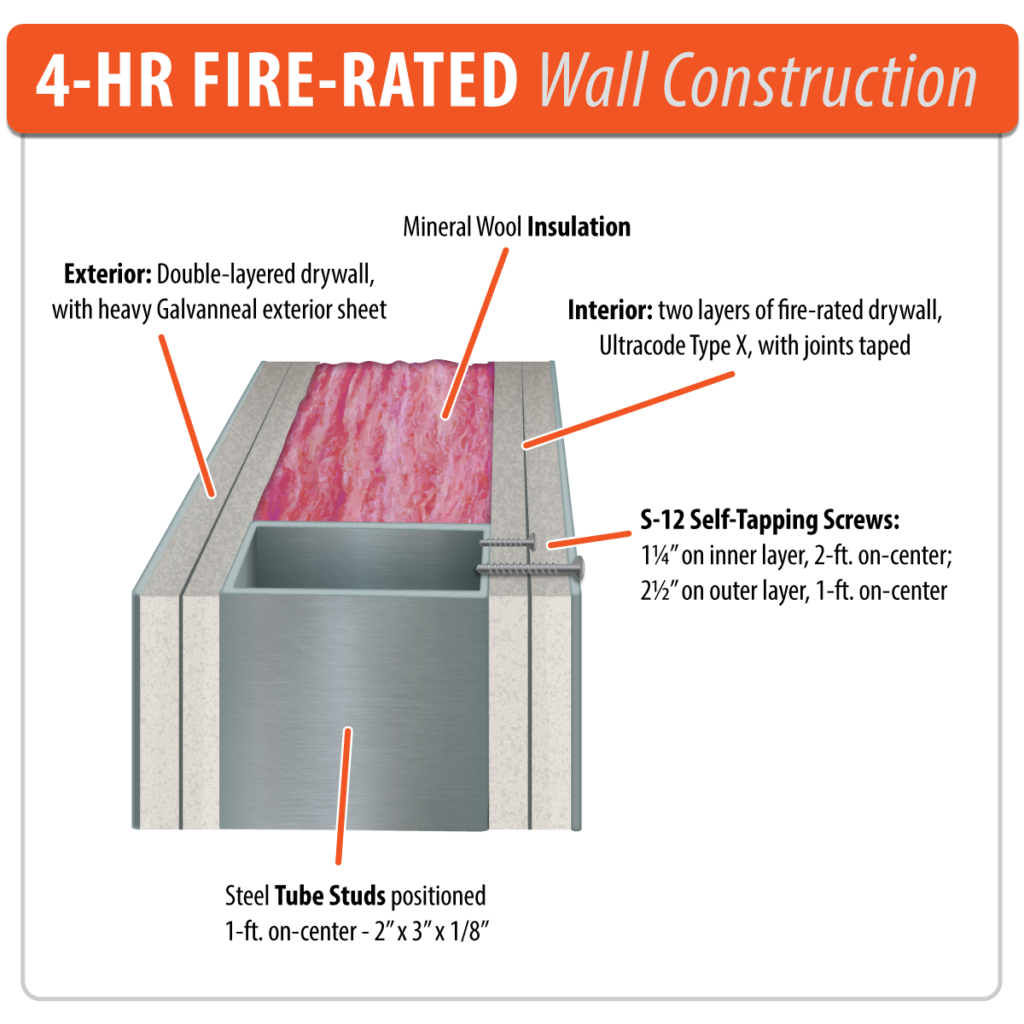

As we’ve said before, oil-based paints contain a large amount amount of hydrocarbons, which are extremely flammable. Paints should be stored in a climate controlled environment to mitigate potential fire hazards and to protect the chemical consistency of each product. Additionally, OSHA mandates that flammable liquids should be stored in a building that is resistant to fire for a certain period of time. When storing flammable paints within 10 feet of sensitive or vulnerable property, you should consider a U.S. Hazmat Rentals 4-hour-fire rated locker. 4-Hour Fire-Rated Structures are engineered and designed specifically for flammable storage safety certification. Our rentals ensure your company will meet all NFPA and OSHA requirements for your chemical storage needs.

When storing hazardous materials or dangerous chemicals within 10 to 30 feet of sensitive or vulnerable property, you should consider a U.S. Hazmat Rentals 2-hour-fire rated locker. Our Two (2) Hour Fire-Rated Structures are designed for storing flammable liquids, chemicals, and combustible materials as required by the authority having jurisdiction. These buildings are rigorously tested to hold their structural integrity for over two hours of intense internal blaze. They will contain a barrage of excessively hot gases, liquids, and solids. In accordance with OSHA 1926.152 and 1910.106, a dry chemical fire suppression system comes standard on fire-rated paint storage buildings. In the event of a fire, this system can quickly douse flames and prevent the fire from spreading. For chemical storage that is 30 feet or more from property lines, equipment or personnel, consider a non-fire-rated storage locker.