Proper chemical storage depends on segregation. Mixing incompatible materials will invariably result in catastrophe. While seemingly inert, otherwise stable chemical compounds can have adverse reactions with hazardous materials from different classifications. Most of these volatile interactions, however, are more subtle than we realize. Container degradation and leaks occur when corrosive materials seep through rusty barrels and inferior plastics. As a result, these free-wielding chemicals will inadvertently mix with airborne vapors or corrode adjacent chemical containers, resulting dangerous interactions. Acids are no exception to the proper storage protocol. While corrosive in nature, acids constitute a bulk of modern industry’s chemical payload. More commonly used in extracting deposits and particulates, acids enhance food flavor and are a powerful catalyst in the production of fertilizer. Compliant acid storage preserves chemical potency while preventing encroachment of vulnerable assets.

Acid Applications and Interactions

Hydrochloric Acid is most commonly used in the neutralization of alkaline agents. From the purification of salt and oil refining to bleaching and steel pickling, hydrochloric acid is a powerful catalyst that can antagonize other precursors. HCL should always be stored in a cool, dry and well-ventilated chemical chemical storage locker. Equipped with optional mechanical ventilation and climate control, our non fire-rated chemical warehouses preserve product consistency and usability. Fire status: not flammable or combustible.

Sulphuric Acid is the quintessential acid and archetype of its class. Used in everything from car batteries and the manufacturing of everyday paints, dyes and fertilizers, this powerful corrosive is one of modern industry’s most tenacious building blocks. But just like every other chemical compound or naturally occurring substance, sulphuric acid is amoral in application and non discriminate in who it affects. When used improperly, sulphuric acid is destructive to human flesh and lungs through inhalation. While inflammable, this type of acid is a powerful oxidizer, enhancing the volatility of other non-compatible chemical substances. For compliant acid storage, inventory sulphuric acid should be stored in a corrosive resistant material, such as polyethylene.

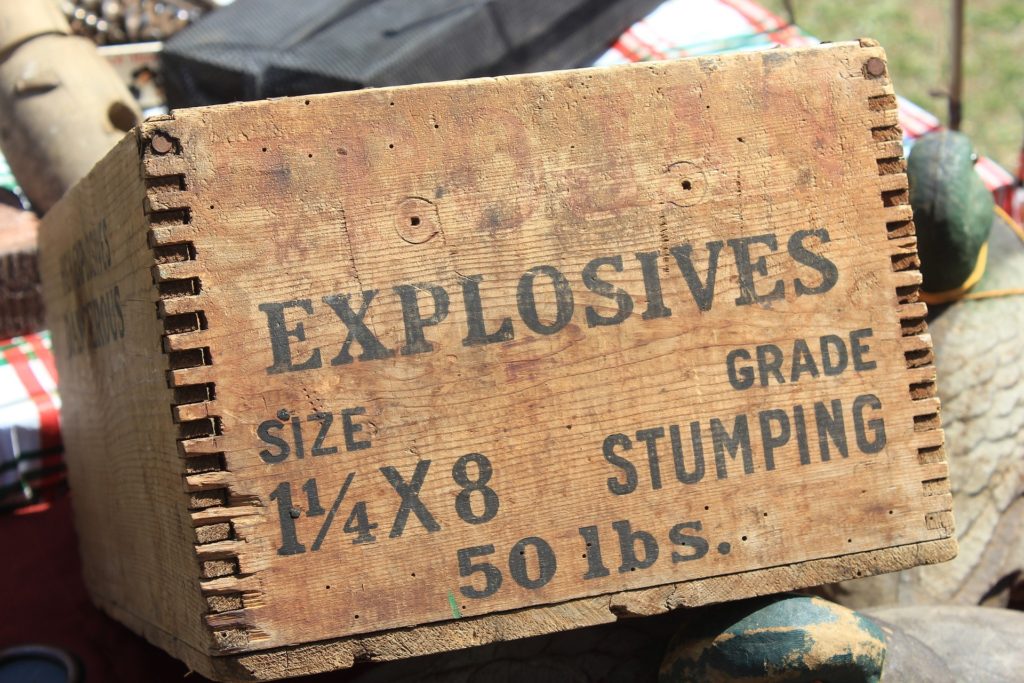

Nitric acid is one of industry’s most powerful building blocks. As a major component in the production of ammonium nitrate, nitric acid is powering industrial scale agriculture. As a volatile chemical catalyst, nitric acid is also used in explosives, such as nitroglycerin and trinitrotoluene. As an oxidizing agent, nitric acid must be stored away from organic compounds, metals and alcohols. Nitric acid should be stored in a cool, dry, well-ventilated storage locker, such as the one below.

What Does an Oxidizer Do?

If you spent any amount of time researching chemical classifications and dangerous interactions, you’ve probably come across the phrase, “oxidizer,” more times than you can count. But what is an oxidizer and how does it affect chemical storage at your workplace? Oxidizers are among the most diverse and versatile chemical agents in industry. As accelerants and catalysts, oxidizers exist as solids, liquids or even as a gas. These agents can react readily with almost any organic materials while exerting virtually no energy. As you could imagine, oxidizers are severe fire hazards. While not inherently prone to sudden fires or combustions, oxidizers can certainly make a dire situation catastrophic by increasing the ignitability of otherwise inert chemicals. Unsurprisingly, many acids fall under the umbrella term of “oxidizing acid” and must be kept away from incompatible materials.

For Compliant Acid Storage, Avoid Storing With Oxidizers and Bases

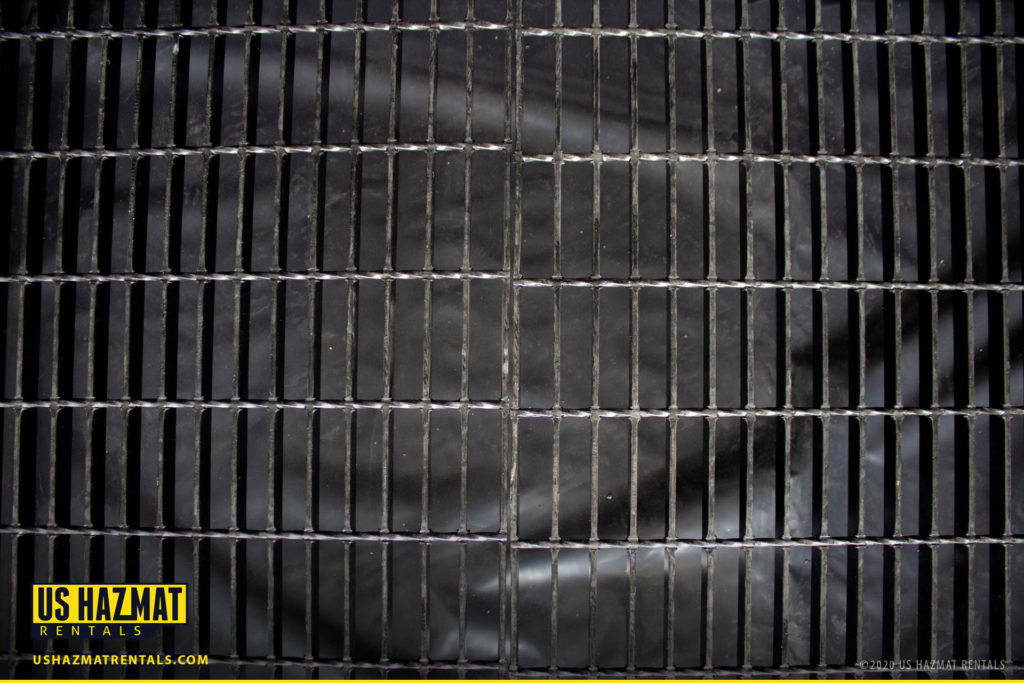

Since most strong acids and caustics will erode most metal cabinets, consider storing these materials in non-metallic or epoxy-painted cabinets. All acids should be stored in a cool, climate controlled environment. Like with any other chemical that you store on the jobsite, consideration must be given to the entire payload and not just individual classifications. For complete chemical segregation, our non fire-rated chemical storage lockers can be compartmentalized and separated with metal partitioned walls to enable to the storage of chemicals from different classifications. Consideration should always be given to spill containment. Sometimes storing incompatible materials separate from one another isn’t enough to prevent catastrophe. What should happen if these chemicals are allowed to interact in the event of a spill? All the due diligence you committed to prevent such inadvertent interactions will be for naught. For complete spill protection, all U.S. Hazmat Rentals fire-rated and non fire-rated storage lockers are outfitted with an innovative spill sump containment system that sits beneath a steel grated flooring. In the event of a spill, the chemical will simply pass through the flooring and into the sump where it will remain until safely removed.