OSHA recently updated its Hazard Communication Standard, reflecting minor additions to the seventh revision of the Globally Harmonized System of Classification and Labelling of Chemicals. Although the agency’s review don’t include significant regulatory overhaul, companies storing dangerous chemicals should read between the lines for nuance. OSHA will likely more stringently regulate chemical labelling and worker communication. Regulatory tweaking could also indicate an increase in unannounced OSHA visits to jobsites and warehouses nationwide. All manufacturers and industries handling hazardous materials must review their onsite OSHA compliant storage for continued adherence to the law.

We provide various-sized flammable and non-flammable chemical storage for small and large manufacturers, warehouses, remote working locations, and municipal infrastructures. Chemical segregation of incompatible materials, centralized storage, and abiding by flammable liquid in storage cabinets secures long and short-term chemical storage. Furthermore, we offer temporary and long-term storage solutions. Our readily-available, quickly deployable chemical storage warehouses ensure continuous onsite protection.

OSHA Compliant Storage Guidelines

- Secure Location: Store chemicals in a safe, secure location, away from direct sunlight, sources of heat, and egress pathways.

- Stable Shelves: Ensure shelves are level, stable, and secured to the wall or another stable surface.

- Hazardous Chemicals: Store hazardous chemicals below eye level.

- Segregation: Separate chemicals that cannot be stored together.

- Container Closure: Keep all chemical containers closed when not in use or for dispensing.

- Labeling: All workplace chemicals should have legible labeling.

- No Clutter: Keep storage areas free from clutter, explosives, and flammable conditions.

- Pest Control: Prevent chemical storage conditions that may encourage rats or pests.

- Distance from Hazards: Place stored materials at least six feet from hoistways and at least 10 feet from exterior walls.

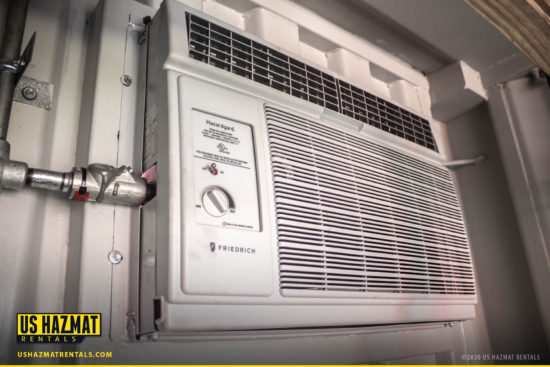

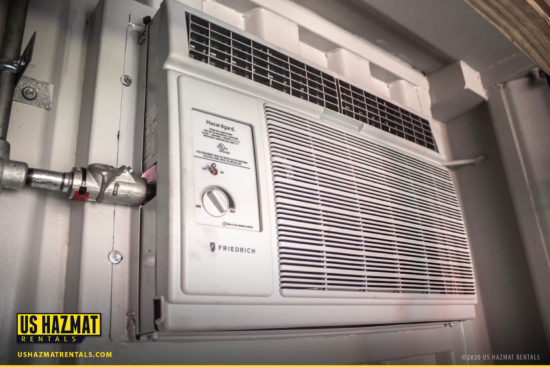

- Ventilation: While not federally required, mechanical ventilation can prevent the toxic buildup of flammable gases and vapors.

Don’t Risk Hefty Civil Penalties, Injuries, and Negative Publicity With Improper Storage

Improper OSHA compliant storage subjects vulnerable companies to several health and environment risks. OSHA fines for improper chemical storage, which are considered “other-than-serious” violations, can range from $0 to $16,550 per violation, while willful or repeated violations can result in fines ranging from $11,823 to $165,514 per violation.

Health Hazards:

- Exposure to Hazardous Substances:Improper storage can lead to leaks, spills, or the release of vapors, exposing individuals to harmful chemicals, potentially causing skin irritation, burns, respiratory problems, or even long-term health effects.

- Contamination: Degraded or improperly sealed containers can allow chemicals to contaminate other materials or the environment, posing health risks to those who come into contact with the contaminated materials.

Safety Hazards:

- Fires and Explosions:Improperly stored flammable or reactive chemicals can ignite or explode, causing serious injuries, property damage, and even fatalities.

- Incompatible Chemical Reactions:Storing incompatible chemicals together can lead to dangerous reactions, generating heat, toxic gases, or even explosions.

- Container Failure:Improper storage conditions (temperature, pressure, etc.) can cause containers to fail, leading to leaks, spills, or explosions.

Environmental Hazards:

- Spills and Leaks: Improper storage can lead to spills and leaks, contaminating soil, water, and air, causing harm to ecosystems and human health.

- Release of Toxic Gases:Some chemicals can release toxic gases when improperly stored, contaminating the air and posing health risks to those nearby.