Life is hard enough. We could all use a cheat sheet to figure out the trickier problems. Why should we find out the hard way through trial and error when a bulleted list of information is readily available at our disposal? Sure, there is value in figuring out real world solutions for everyday problems, but the purpose of technology – or at applied knowledge – is benefiting from the experience of those who’ve gone before us. In industrial manufacturing, we call these sheets “safety data sheets.”

As you can tell just from the funny sounding name of most chemicals, understanding hazardous materials is like trying to decipher a foreign language. It’s hard enough just trying to pronounce hydroxyphenol, but trying to understand the complete chemical synthesis and impact as a biotoxin might take a background in chemistry and biology. Fortunately, safety data sheets help bridge that gap so employers can keep employees safe.

What are Safety Data Sheets?

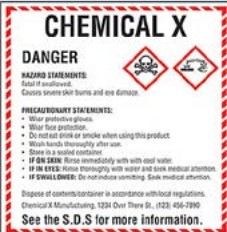

Information is a powerful weapon to avoiding threats and injuries. Actually, it can be our best tool as precaution and avoiding unnecessary interaction is a cornerstone to proper chemical safety. Safety data sheets help bridge that gap. In simplest terms, safety data sheets contain detailed information on chemicals that describe its physical and chemical properties, as well as any possible health hazards of that chemical and what to do if inadvertently exposed to it.

You can think of a safety data sheet as an expanded warning label that lists all possible dangers and risks associated with using a specific chemical. By law, manufacturers must provide individualized safety data sheets for each individual chemical they make when shipping it to the consumer. Employers who purchase the chemical from the manufacturer must then allow easy access to the sheets to employees if they are to come in contact or use the dangerous chemical.

What Do Safety Data Sheets Include?

- Describes physical and chemical properties of the hazardous material.

- Possible physical and health hazards associated with the specified chemical.

- Precautions for safe handling and use.

- Emergency first-aid procedures.

- Control measures for using and storing dangerous chemical.

When to Use Safety Data Sheets

OSHA examines the usage of chemicals in the workplace and jobsite under two different classifications: consumer and occupational usage. Consumer usage refers to the use of the product in the same way a consumer would – sporadically and situationally without consistent exposure, such as petroleum products when changing oil or servicing your car. Occupational usage refers to the chemical application to perform a specific job or duty. This also refers to the everyday handling and exposure of a chemical by the employee. While the novice mechanic who changes his oil every three months wouldn’t need a safety data sheet, the seasoned pro who does it everyday for a living would. The difference is in frequency of use. SDS also have value in training new employees.

Veterans might also return to these sheets as a refresher course on a chemical they haven’t used in a while. Either way, employers must provide easy access to the sheets. In other words, they can’t just stuff them in a folder or hang them on a bulletin board behind the snack machine. Employees must also be trained on how to read and apply the safety data sheets of each chemical. If a company is using one type of hazardous material, chances become high they are using other dangerous chemicals. For this reason, each company must have a safety data sheet on hand for every dangerous chemical within the facility.

Safety Data Sheets and Chemical Storage

Along with dire safety information, a SDS provides recommendations for product use and storage, as well as clean-up. For example, a SDS might recommend fire-rated storage for flammable or combustible materials, such as ethanol. This is where compliant chemical storage enters the equation. If a safety data sheet is the cautionary advice on how to handle a hazardous material, a fire-rated chemical storage locker is the real world solution. It’s caution in action, and takes out the guesswork in complying with stringent OSHA regulations. While it’s important to carefully study and rehearse the strategy outlined in SDS, a chemical storage locker is an overarching solution that ensures your compliancy.

Chemical storage lockers from U.S. Hazmat Rentals assuage your fears of compliance. Instead of having to constantly refer back to your SDS to make sure you got the right chemical storage on site, our fire rated storage lockers will have you cover. Our chemical storage advisors have become walking talking Safety Data Sheets. They have more than four decades of experience when it comes to storing every dangerous chemical imaginable. They will make sure you have the correct chemical storage container on-site, as outlined in the safety data sheet. Our chemical storage lockers provide protection and compliant storage for every potential risk and application.