Chemical storage is full of hidden dangers. From small inventories to expansive warehouses, silent threats abound. Incompatible storage is a leading culprit for dangerous chemical incidents. Without proper safeguards in place, dangerous chemicals can interact, resulting in fire or the release of toxic vapors. Flammable materials and corrosive substances should never interact, nor should oxidizers with other unstable substances. Inadequate ventilation and the lack of climate control can compromise dangerous substances and affect the chemical consistency and application of products. With all of these obvious threats lurking in the background of your business, it can be hard to smoothly operate and serve customers. But what about the not so clearly visible hazards. What about the hidden dangers of chemical storage? U.S. Hazmat Rentals can provide expert advise and guide your business to the most cost-effective chemical storage solution.

The Dangers of Static Electricity and Errant Sparks

When it comes to improper chemical storage, sometimes all it takes is just a spark to set your life’s work ablaze. Some of industry’s most catastrophic incidents began from the most unlikely of sources. Static electricity is that invisible accelerant that exists in almost any work environment. It’s just as common and potentially dangerous as the air we breath on any job-site. Static charges originate from friction. Unlike powerful transformers and electric lines, static electricity might seem rather innocuous. Have you ever walked across a carpeted floor in socks before touching a door knob? Did you feel that spark? While it might’ve felt relatively harmless, imagine if this spark occurred in the presence of gasoline fumes? Most chemical incidents involving static electricity happen during transport or transferring. For example, while pouring chemicals from a larger barrel into a smaller tote, a worker might be tempted to wipe off the excess or spilled liquid from the lid of the container with a dry rag. Suddenly, the friction of this rag causes a small spark that turns into a fireball the engulfs the worker and the entire company floor.

To mitigate the threats from static electricity, OSHA requires the proper bonding and grounding of chemical barrels during the transfer or distribution of liquids. NPFA 77 also provides stringent oversight concerning chemical storage and static electricity. OSHA provides strict guidelines for bonding containers when dealing with Category 1 and 2 flammable liquids. U.S. Hazmat Rentals provides a lines of sterile and sleek chemical storage lockers that discourage any incompatible material storage or practices that might allow for the discharge of dangerous sparks.

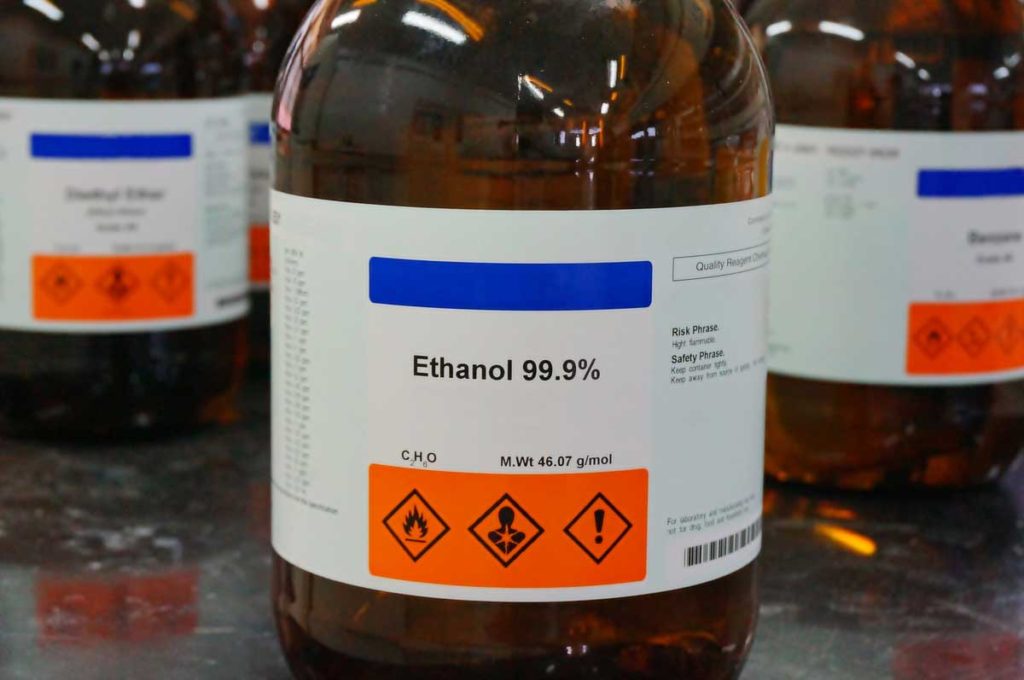

The Perils of Improper Labeling

Everything has a place. Organization is the key to efficiency and replenishing of goods that provide needed services. But what provides proper direction for this organization? Correct product labeling prevents incompatible materials or noncongruent substances from interacting. Would you store gasoline in proximity to chlorine? Or store flammable or corrosive materials in plastic containers that are prone to melting? Of course not. Federal guidelines require clear and direct language for labeling dangerous chemicals. OSHA requires product identifiers, signal words, hazard statements, pictograms, along with other pertinent information on all labels for chemical containers. When it comes to proper chemical storage, segregation is just important as organization and proper labeling. Our fire-rated chemical storage lockers feature metal partition walls that prevent incompatible materials from interacting. Taking precautions today for proper organization and labeling can help thwart the hidden dangers of chemical storage tomorrow.