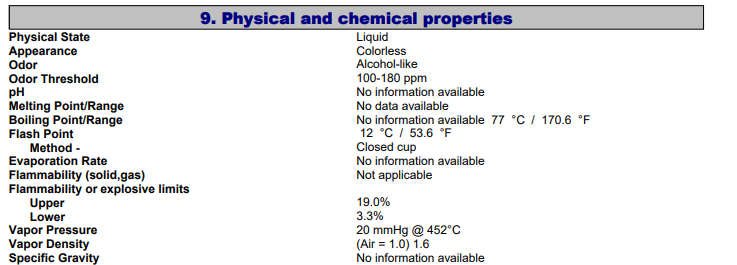

A material safety data sheet is the ultimate go-to for handling and storing hazardous materials. Manufacturers and heavy industries should have a MSDS sheet for every classification and type of hazardous material used at your jobsite. For example, a MSDS for ethanol is separate and unique from a propane safety data sheet. Expansive in nature, a MSDS provides concise details of each relevant hazardous chemical, including chemical properties, a list of incompatible materials, known hazards, flash and boiling points, first aid measures, and general storage guidelines. Moreover, each MSDS should be readily available and visible in proximity to any hazardous material used in your facility’s workflow processes.

Why is a MSDS Important?

Worker safety is a central part of the function of OSHA. An MSDS sheet ensures employees and manufacturers follow safe material handling in each industry. While OSHA enforces thousands of workplace safety regulations, MSDS is only concerned with hazardous chemicals. Safety data sheets are written in an easy-to-read format with direct information on the known risks and mitigations for dangerous chemical events. An MSDS sheet begins with information on the molecular composition of a specific chemical and common industry names for easy identification. Moreover, a safety data sheet invariably includes hazard pictograms. Each red diamond-shaped pictogram depicts all the hazards associated with the chemical. For example, a skull and crossbones pictogram warns of human toxicity. A jagged flame pictogram is the signal word for fire. Although hazard pictograms are helpful in quickly discerning potential hazard threats, it’s also essential to understand appropriate first aid measures for accidental exposure to dangerous chemicals.

What Does A MSDS Sheet Say About Fire Suppression?

Each MSDS sheet will include information concerning fire protection. Moreover, each chemical’s MSDS will list suitable extinguishing agents and what measures firefighters should take when responding to chemical fires. Using an inappropriate extinguishing agent could be a catalyst for certain types of chemical fires, so referring to the chemical’s MSDS for safe fire-fighting protocols is critical. MSDS sheets protect your employees and the community members you serve. Furthermore, chemical safety data sheets guide accidental releases and environmental protection. U.S. Hazmat Rentals provides compliant fire suppression systems that can be remotely activated during a fire through ceiling-mounted pipes. By assessing your chemical storage needs, we can implement the fire-suppression system and extinguishing agent right for your chemical payload.

Safety Data Sheets and Chemical Storage

Most MSDS sheets provide a list of incompatible materials for each hazardous material. Avoid storing hazardous materials in the same chemical storage locker or container as the referenced MSDS chemical. For example, never store chemicals like methanol near oxidizing agents and acids. Our compartmentalized chemical storage lockers prevent accidental exposure between incompatible materials ensuring NFPA 30 and OSHA compliance. Segregated chemical storage is also conducive to efficient organization, logistics, procurement, and time management. Each U.S. Hazmat Rentals storage locker is outfitted with safety features such as climate control and ventilation, addressing every need of each specific MSDS sheet. Contact us today for a free quote and consultation.