Understanding proper chemical segregation from incompatible materials is one of the most common questions we hear from customers. Proper chemical segregation requires a sharp, inquisitive mind. So, congratulations! You’re already thinking ahead of the learning curve in securing compliant protection for your chemical stockpiles. While reviewing OSHA-compliant storage regulations is tedious, commonsense prevails in solving most storage dilemmas. OSHA requires any flammable material exceeding 25 gallons to be stored in a separate chemical warehouse or storage locker. Obtaining reliable onsite protection that meets NFPA30 standards ensures lasting compliance and worksite safety. When in doubt, trust the experts at U.S. Hazmat Rentals as a knowledgeable guide in all hazmat-related matters. Experience matters in the volatile world of chemical storage, and we’re here to help!

Storing Dangerous Chemicals by Hazard Classification and Group

There’s no grey zone in storing dangerous chemicals by classification. Hazardous materials that pose significant harm to property and personnel should always be stored in a separate storage area, cabinet, or designated shelving. Secure product inventorying includes physically separating hazardous materials from sensitive areas. Federal regulators have spelled it out in black and white – ignorance is no excuse for compliant chemical storage. Hazardous materials should be stored based on their physical properties and reactivity to incompatible materials. Hazardous materials with low flashpoints and a high propensity to fire and explosion require superior protection and should always be stored separately from potential accelerants. Failure to properly store hazardous materials could lead to injury, destruction, hefty civil penalties, and in extreme scenarios – death.

Carefully Read Product Labels When Segregating Incompatible Materials

Have you ever tried to assemble patio furniture without reading the directions? (Hopefully, you didn’t try to assemble by reading the French instructions before flipping the page to find the English section!) Gentle unfurrowing of the brow and inquisitive ascending eyebrows from your skeptical wife, who was left questioning how you would entertain guests on your newest haphazardly assembled gadget, was not your finest moment as a DIY’er. The stakes are more dire with dangerous chemicals. One faulty misstep can send your chemical stockpiles skyward before profits return to Earth. Each chemical’s respective label includes hazard warnings and storage recommendations. Chemicals without labeling should be immediately discarded in an appropriate hazardous waste receptacle if the origin cannot be determined.

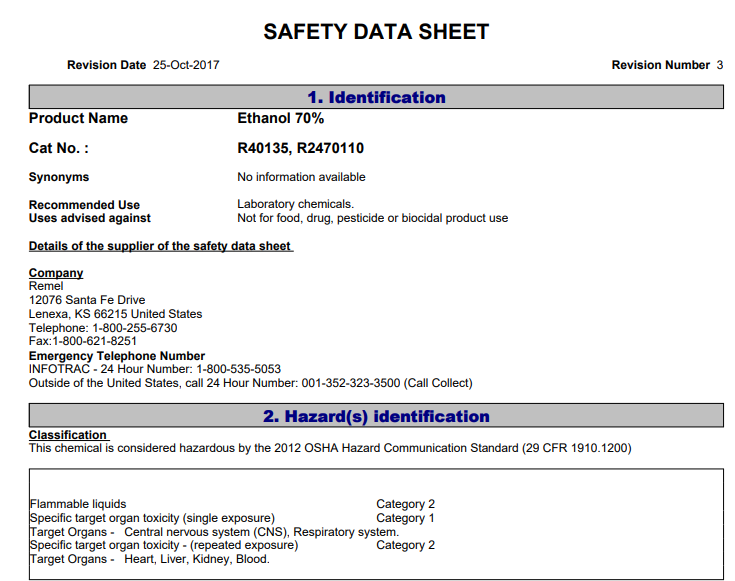

Consult the Chemical’s Material Safety Data Sheet

Each hazardous material has an easily accessible material safety data sheet. Each MSDS is separate from another hazardous material product sheet. For example, the MSDS for Benzene is separate from the ethanol data sheets. Although industrial manufacturers should provide an MSDS for each product shipped to your warehouse, relevant safety data sheets can be easily found online. An MSDS contains essential information about the aforementioned dangerous chemical you’re handling. An MSDS also discloses the chemical’s physical and chemical properties, specific flashpoints, and boiling points. Furthermore, an MSDS provides the chemical’s noncompatible materials and appropriate fire-fighting suppressants. Finally, an MSDS details best storage practices for dangerous chemicals to guide the compliant storage process further.

What Size, Type Chemical Storage is Right for Me?

The necessary chemical storage locker size is based on stockpile quantity. Larger inventories require more significant, and stronger attention. Incompatible materials more commonly require separate storage protection. While locker customization differs upon customer need, rest assured that our talented building engineers will render a solution that meets all standards under your authority having jurisdiction. Each U.S. Hazmat Rentals’ storage locker is outfitted with superior galvanized steel paneling, enveloping a steel-framed tubular skeleton, protecting volatile chemicals from adjacent vulnerable equipment and staff. We don’t skimp on safety while fabricating the chemical storage locker best suited for your chemical needs. From top to bottom, we have your stockpiles protected, which is why each hazmat warehouse is also reinforced with multiple layers of 12 gauge steel roof protection with optional explosion relief panels, minimizing potential blast radiuses for possible fires and explosions.

Secure, Secondary Containment for Chemical Storage Warehouses

Secondary containment for spilled chemicals is your final stopgap for environmental pollution and employee exposure. These universal catch trays, lined with a high density Polyethylene 20 mil sump liner, catch spilled chemicals that pass through the steel-grated floor until safe extraction. Innovative spill sump containment is a crucial element in achieving compliance fore segregating incompatible materials.

Trust the Experts for All Temporary Chemical Storage Needs

Understanding complicated OSHA regulations for chemical storage is daunting. Allow our trusted building advisors to guide you through this process. We can quickly evaluate your facility’s needs before providing rapidly-deployable chemical storage solutions for any workflow or environment. All chemical storage warehouses are available for short and long-term storage dilemmas. Don’t risk compliancy. Contact us today for a free quote and consultation!