When it comes to chemical incidents and environmental incursions, there are no such things as isolated events. While accidental pollution and contamination of any magnitude are always a cause of concern, spills that occur during transit take on a more sinister moniker. Waterways are particularly vulnerable to widespread contamination as microscopic toxins can infiltrate groundwater before killing off marine organisms that are vital lynchpins in our larger food chains. With the foresight of protecting our pristine ecosystems, the highly enforceable EPA shipping requirements underscore the importance of responsible maritime transport of dangerous chemicals.. U.S. Hazmat Rentals can help your onshore operations safeguard against accidental contamination with segregated chemical storage to streamline logistics and inventorying.

Francis Scott Key Bridge Collapse Triggers Environmental Concerns

Last week’s collapse of the Francis Scott Key Bridge brings into question not only our decaying national infrastructure but also whether shipping operations are doing enough to protect against large scale environmental catastrophes. While we would never minimize the loss of life of the six construction workers who died when the disabled cargo ship sundered the longstanding Baltimore landmark, we should also not ignore the potential environmental disaster buoying above the calm waters of the Baltimore Harbor. Exacerbating the monumental collision are reports that some of the cargo ship’s chemical containers were breached following the jolting bolt to the ship’s bow. Altogether, the vessel contains 764 tons of corrosive and flammable materials, including batteries. While the extent of the breach is unknown, even a slight infliction of the container’s structural integrity could unleash large volumes of highly toxic material into the ecosystem.

EPA Shipping Requirements Protect Fragile Ecosystems

Federal agencies have developed numerous comprehensive guidelines for importing and exporting hazardous materials. If you’ve spent time procuring or implementing hazardous materials into your workflow operations, you’ve undoubtedly come across a product safety data sheet. In short, product safety data sheets provide condense information for every hazardous chemical subject to governmental regulation. A safety data sheet includes potentially toxic properties of each chemical, as well as protective measures and safety precautions for handling such materials. When shipping hazardous materials, all transporters, whether on the highway or waterways, must provide a SDS to whoever is handling the dangerous materials. Ultimately, the SDS provides guidance while commanding attention to the dangerous chemical on board.

EPA shipping requirements extend beyond simple chemical classification and hazard communication. The U.S. Department of Homeland Security also outlines the importance of responsible packaging and segregation of hazardous materials as the foundations of the shipper’s responsibilities. Invariably, the bulk of hazardous materials will be transported by sea in shipping containers, posing logistical and environmental challenges. Shipping containers often sit atop the cargo ship’s deck in towering configurations, potentially exposing volatile and temperature-sensitive dangerous chemicals to various adverse weather conditions. While the presence of an SDS can mitigate most of these chemical cargo challenges by allocating the appropriate safeguards for segregation, the protocols do not always extend to protection against degradation.

Dockside Flammable Chemical Storage Lockers Safeguard Against Contamination, Compositional Breakdown

While the EPA Shipping Requirements strive for accountability and environmental protection, they don’t mitigate the scope of challenges for transporting hazardous materials. Federal regulations can be onerous and sclerotic in nature. Although federal regulations vouchsafe a wealth of information for the safe transport of dangerous chemicals they don’t take into consideration cost-effectiveness. Remember, EPA Shipping Requirements exist for environmental protection, not your bottom line or shareholders’ profits. While developed in an abundance of caution, rigid hazmat shipping requirements can often encumber logistics and inventorying. Most dangerous yet necessary volatile chemicals have a short shelf-life so quick shipment is paramount in maintaining workflow operations that hinge upon timely orders. Lengthy voyages compounded by time-consuming dockside inspections can subject inventory to adverse temperatures that could lead to compositional breakdowns, reducing the effectiveness of lubricants, pesticides, and precursor chemicals.

U.S. Hazmat Rentals flammable chemical storage lockers can reduce the time expensive chemicals are subject to weather conditions that negatively impact compositional integrity. Dockside chemical container lockers can streamline shipping operations by providing climate-controlled storage for expensive hazardous materials before shipping. Large-scale manufacturers can benefit from dockside or nearby chemical storage by having an onsite hazmat locker to house sensitive chemicals before being loaded into shipping containers. Procuring chemical storage near ports also provides a crucial stopgap for delays, which are common in today’s shipping industry. In the event of delays, crews can relocate temperature-sensitive chemical stockpiles to our climate-controlled storage lockers until they are ready for transport, further assisting inventorying and logistics protocols.

Enhanced Steel Protection for All Stages of Production

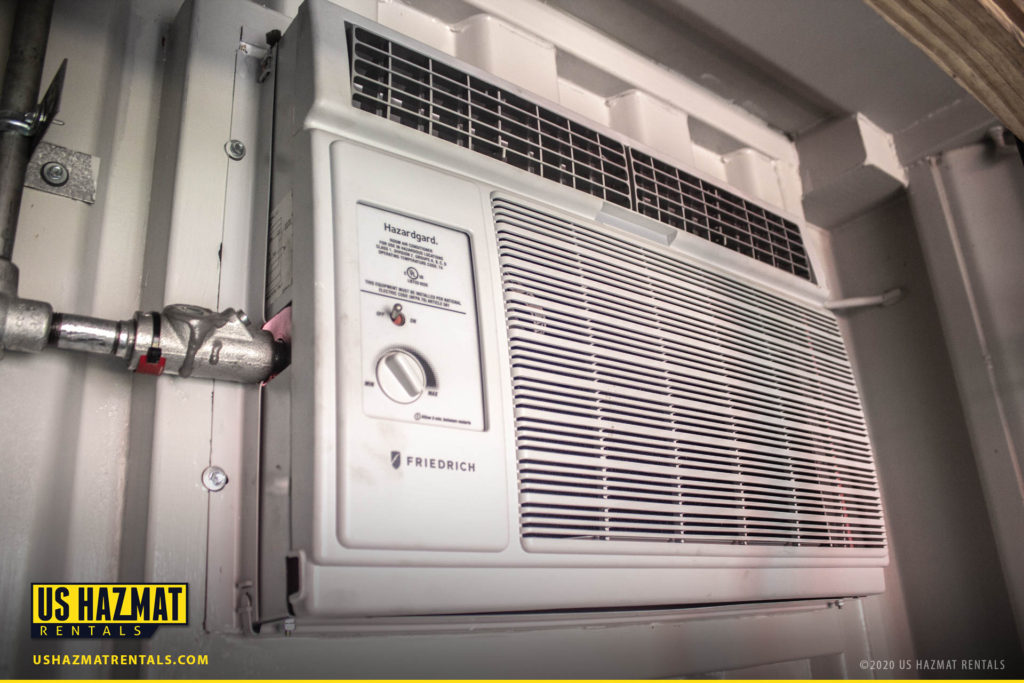

A cursory review of our chemical storage lockers might remind you of the everyday shipping containers used for oceanic transport. In fact, you might think our chemical warehouses and shipping containers are one in the same, but a detailed look inside would leave little doubt about the superior steel protection of our fire-rated storage lockers. Our chemical storage warehouses are like shipping containers on steroids. Every locker that rolls off our factory floor is reinforced with solid steel welds and explosion relief panels to minimize potential catastrophe. Optional mechanical ventilation, climate control, and fire suppression offers an additional level of protection for not only preventing inadvertent fires through segregated storage, but as well as protecting the consistency and composition of dangerous chemicals.

Each locker also comes with an innovative spill sump containment system affixed to the bottom of the locker. In the event of the spill, the stored chemical will simply pass through the locker’s steel-grated flooring and into a large sump where it will remain until safe extraction. Furthermore, our BoxSafe chemical storage rentals meet the demanding needs of both your budget and EPA shipping requirements. Each ISO conversion box is capable of storing anywhere from 25-50 drums, maximizing workflow operations.