Flammable chemicals need top-of-the-line protection. Although the National Fire Protection Associated has written more than 300 standards for handling hazardous materials, extra consideration is given to combustibles. Most flammable chemicals have low flash points, or the lowest temperature a chemical concentration can ignite the surrounding air. Flammable chemicals cause an 8,000 average of industrial fires annually. OSHA limits the storage of flammable or combustible liquids to 25 gallons in a room outside an approved storage container. OSHA also stipulates that no more 60 gallons of flammable materials with a flashpoint at or below 140 can be stored in an approved hazmat warehouse. Larger stockpiles are given special attention. OSHA requires no more than 120 gallons of combustibles with a flashpoint at or above 140 degrees can be stored in a hazmat warehouse.

Not more than 60 gallons of Category 1, 2 and/or 3 flammable liquids or 120 gallons of Category 4 flammable liquids shall be stored in any one storage cabinet. Not more than three such cabinets may be located in a single storage area. Quantities in excess of this shall be stored in an inside storage room.

OSHA 1926.152(b)(3)

Only in specialized warehouse storage areas and in our US Hazmat Rentals storage buildings – designed, engineered, and construction for greater storage volumes – can high-quantities of flammable liquids and materials be property stored.

What Are the Classifications of Flammable Liquids

Below is a list of requirements for flammable liquids classification. Understanding NFPA 30 is critical in securing compliant storage protection.

- Class I Liquids: Flammable liquids that have a flash point below 100°F (37.8°C). They are further divided into three categories based on their volatility:

- Class IA: Liquids with a flash point below 73°F (22.8°C) and a boiling point below 100°F (37.8°C).

- Class IB: Liquids with a flash point below 73°F (22.8°C) and a boiling point at or above 100°F (37.8°C).

- Class IC: Liquids with a flash point at or above 73°F (22.8°C) and below 100°F (37.8°C).

- Class II Liquids: Combustible liquids with a flash point at or above 100°F (37.8°C) and below 140°F (60°C). They are also divided into three categories based on their flash points.

- Class IIIA Liquids: Combustible liquids with a flash point at or above 140°F (60°C) and below 200°F (93.4°C).

- Class IIIB Liquids: Combustible liquids with a flash point at or above 200°F (93.4°C).

All Category I, II, or III flammable liquids should be kept in closed containers when not in use.

Superior Fire-Suppression Technology

OSHA requires at least “one portable fire extinguisher having a rating of not less than 20-B units shall be located not less than 25 feet, nor more than 75 feet from any flammable liquid storage area located outside.” Where sprinklers are provided, these fixtures must be installed in accordance with the Standard for the Installation of Sprinkler Systems. Our dry chemical fire suppression is available on our two and four-hour fire-rated flammable chemicals warehouse. If a fire should occur inside the chemical storage locker, the overhead pipes will quickly douse the flames with an extinguishing agent. Although a wide dispersion system is ideal for larger stockpiles, we also provide manual pull stations that enable individual sprinklers to concentrate on isolated blazes.

Mechanical Ventilation Reduces Fire Risks

Flammable chemicals have silent, but deadly risks. Small, slow leaks will often go unnoticed. Toxic vapors can inadvertently cause fires if allowed to accumulate inside a hazmat warehouse. Portable tanks not exceeding 660 gallons must have emergency venting in accordance with chapters II and III of the The Flammable and Combustible Liquids Code, NFPA 30-1969. Our optional explosion-proof ventilation system reduces the risk of fire by making six air changes per hour at a rate of no less than one cubic foot per minute.

Storage Capacities and Signage

NFPA 30 Section 9.5 says the total volume for storage of Class I, Class II, and Class IIIA liquids should not surpass 120 gallons in a single storage locker or cabinet. Additionally, all flammable gases should be stored in a well-ventilated OSHA approved hazmat locker. Each chemical storage cabinet or warehouse should display “FLAMMABLE” and “KEEP FIRE AWAY” signage and markings. Each letter height for “FLAMMABLE” should be two inches while the minimum letter height for “KEEP FIRE AWAY” should be one inch. Although NFPA 30 Section 9.5 also guides flammable liquid storage in a wooden cabinet, we recommend a steel solution. Our fire-rated chemical storage lockers are comprised of superior steel sheeting and solid steel welds offering maximum strength of protection. Furthermore, our chemical storage lockers also meet the NFPA 30 Section 9.5 requirements for riveted or welded structural joints.

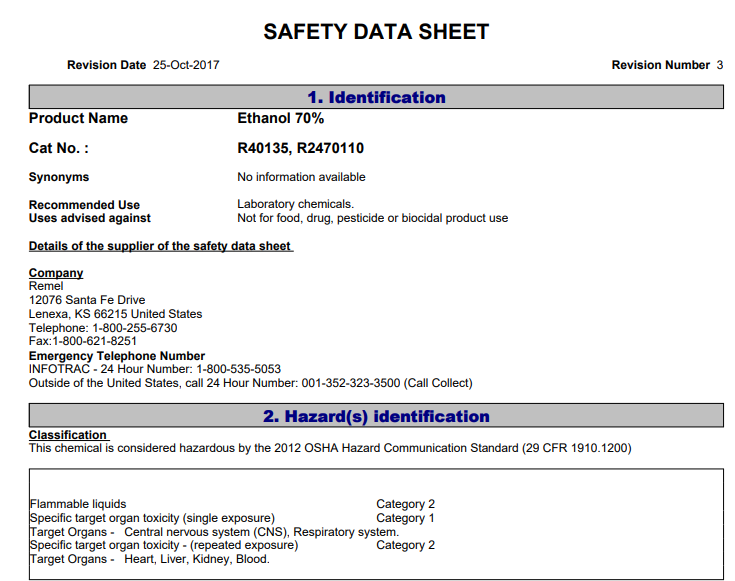

Always Have a Material Safety Data Sheet Available for Each Flammable Liquid

Material safety data sheets provide condense and concise information for each OSHA regulated hazardous material. The NFPA and OSHA have developed an individual MSDS for every hazardous chemical. Each MSDS is unique and separate from other regulated flammable chemicals. For example, the MSDS for ethanol is different than the sheet for benzene. In addition to providing specific properties of each hazardous material, a MSDS also defines appropriate first-aid measures and storage guidelines. All relevant MSDS should be made readily available for each flammable liquid on your jobsite

Routine inspection and maintenance of hazardous materials storage containers can prevent inadvertent chemical incidents from accidental releases of flammable chemicals. All handlers of dangerous materials must establish a schedule for routine inspections and maintenance of storage containers, equipment, and facilities to identify and address potential hazards or deficiencies. Keeping thorough records of inspections, maintenance activities, and corrective measures taken to demonstrate compliance with NFPA 30 requirements will ensure lasting protection