Hazardous Storage Area Regulations

OSHA, under the tutelage of the National Fire Protection Associated, enforces regulations concerning your company’s hazardous material storage area. Each industry that handles hazardous chemicals for producing finished goods or incurring residual hazardous waste must follow hazardous material storage area regulations. A hazardous material is any potentially volatile or dangerous chemical that poses known adverse reactions, health hazards, and environmental contamination risks. Failure to abide by OSHA and NFPA 30 regulations for hazardous materials storage area can result in civil penalties. While safety is a guiding principle of compliant chemical storage, special precautions should also be taken to contain environmental pollution. Although state regulations vary, our hazardous materials storage area warehouses can ensure lasting protection and compliance.

Not more than 60 gallons of Category 1, 2 and/or 3 flammable liquids or 120 gallons of Category 4 flammable liquids shall be stored in any one storage cabinet. Not more than three such cabinets may be located in a single storage area. Quantities in excess of this shall be stored in an inside storage room.

OSHA 1926.152(b)(3)

FREE Consultation

Contact us for a free consultation with one of our Hazardous Chemical and Flammable Material Storage experts. Service is our business. Summarize your project and we’ll connect with you to discuss your storage options and compliance.

Hazardous Storage Area Regulations

How Much Hazardous Material is Permittable?

OSHA allows for the storage of 25 gallons of flammable liquid outside a compliant storage container. Additionally, OSHA requires no more than 60 gallons of flammable liquid (flashpoint below 140 degrees F) or 120 gallons of combustible (flashpoint at or above 140 degrees F) can be stored in a single chemical storage container or warehouse. Moreover, OSHA requires the use of rated storage safety cabinets when possible. Although federal requirements per chemical vary, our fire-rated and non fire-rated chemical storage lockers can ensure workplace compliance for temporary storage dilemmas.

Ensure safety and compliance with federal regulations around hazardous material and chemical storage areas.

Only in specialized warehouse storage areas and in our US Hazmat Rentals storage buildings – designed, engineered, and construction for greater storage volumes – can high-quantities of flammable liquids and materials be property stored.

How Should I Store Hazardous Materials Inside a Hazmat Locker?

Hazardous materials must always be stored below eye level. Additionally, hazardous materials should never be stored on the floor or unstable surfaces such as ledges, egresses, tilted shelving, or in older chemical drums susceptible to leaks. All hazardous material containers must be closed until and after dispensing and mixing. Moreover, all chemical containers should be properly labeled ensuring proper application and storage. While it might sound counterintuitive, avoid storing hazardous materials alphabetically. Federal regulations allow for the storage and removal of hazardous materials by hand truck or forklift. Our innovative pushback racking and wide-swinging doors allow for the easy storage and removal of hazardous materials in drums or IBC tote pallet systems.

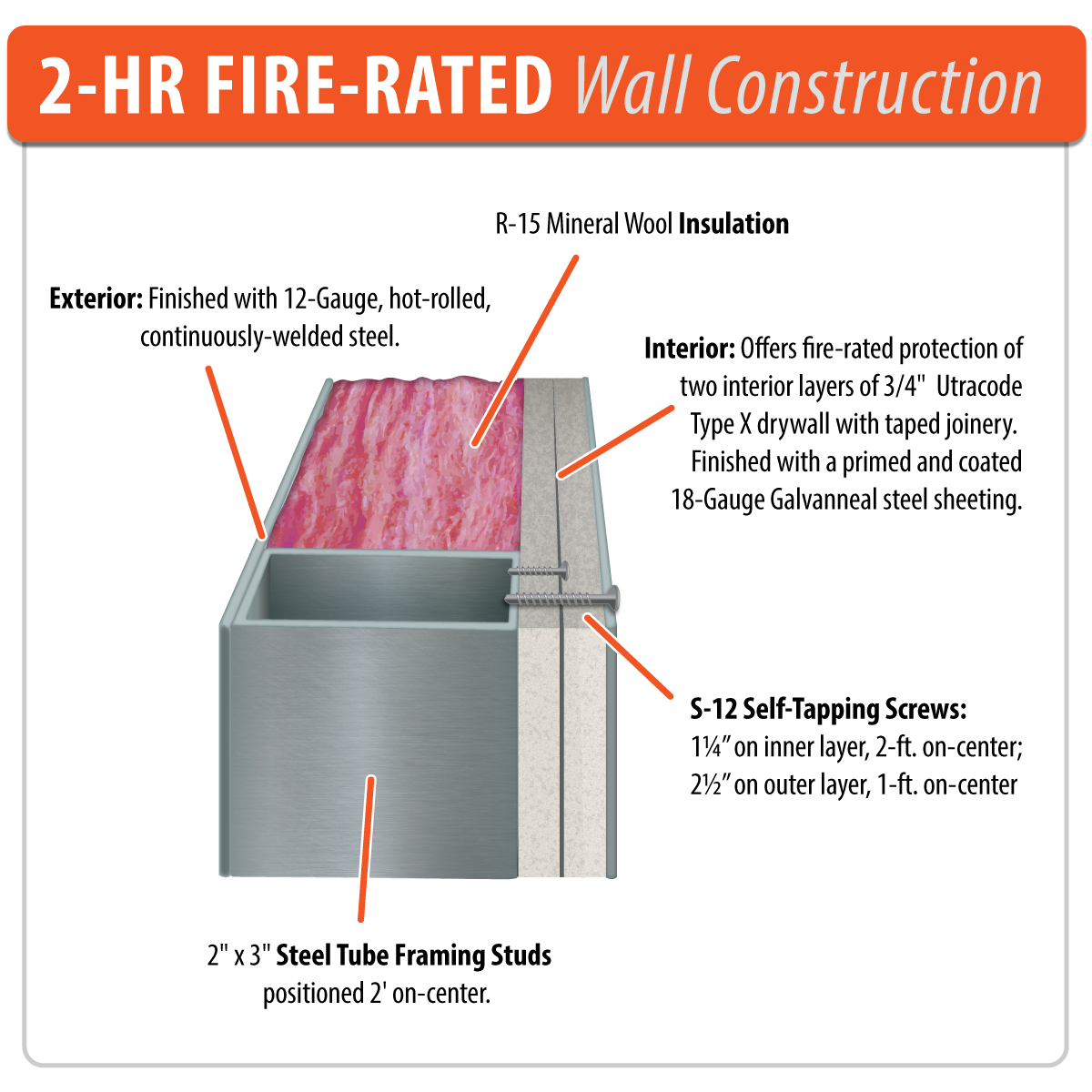

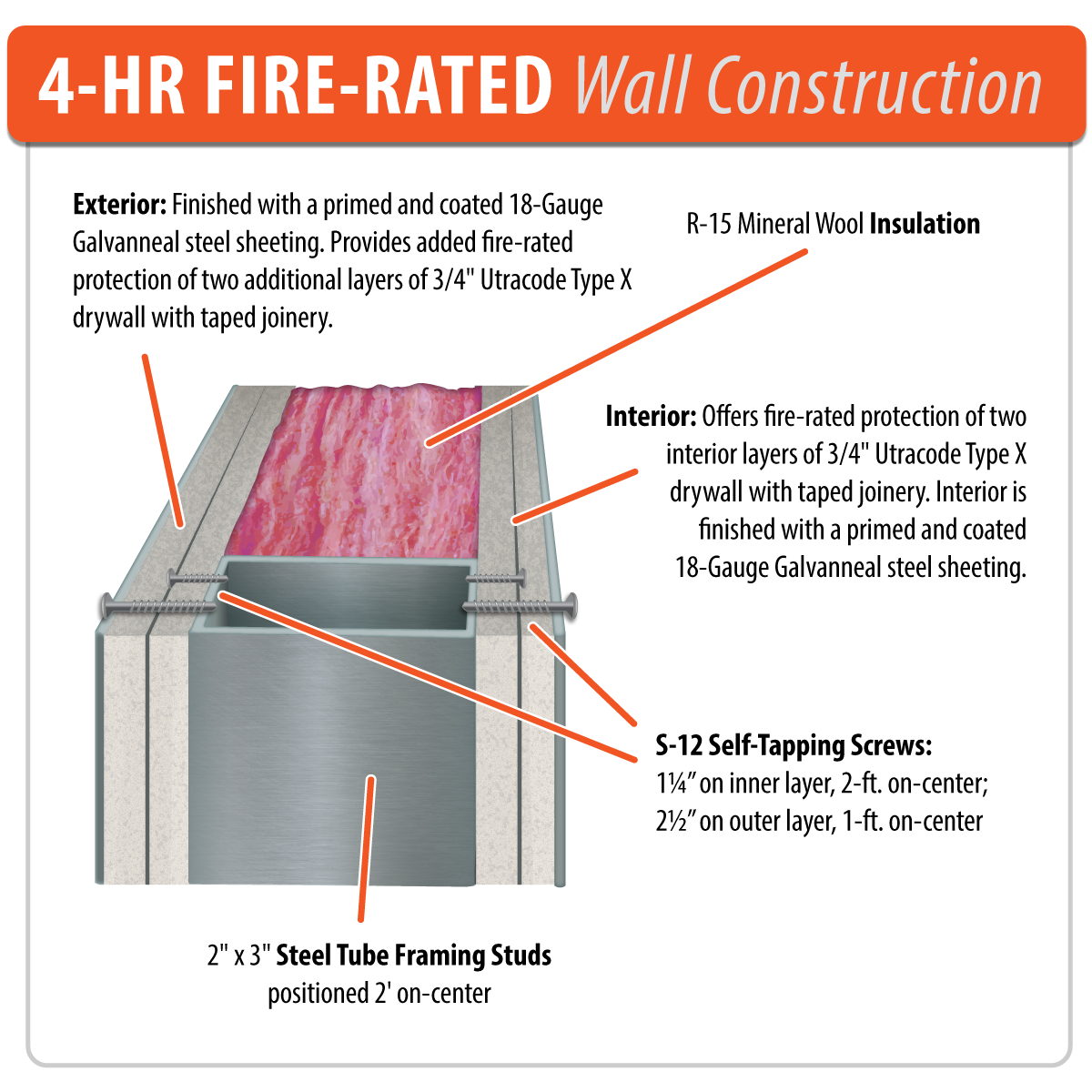

What are Acceptable Building Materials for a Hazardous Material Storage Area?

OSHA regulations allow for the wooden and steel construction of hazardous material storage areas. Because of the potential volatility for dangerous chemicals, OSHA requires all wooden storage cabinets to be constructed with exterior grade plywood at least 1 inch in thickness. Furthermore, the wooden chemical storage cabinet should not breakdown under standard fire test conditions. All joints must be rabbeted and fastened in two directions with flathead wooden screws. A rabbeted overlap of no less than 1 inch is permitted when more than one door is used. “Steel hinges shall be mounted in such a manner as to not lose their holding capacity due to loosening or burning out of the screws when subjected to fire. Such cabinets shall be painted inside and out with fire retardant paint,” according to OSHA Standard 1926.152.

Furthermore, OSHA stipulates that no more than “60 gallons of Category 1, 2 and/or 3 flammable liquids or 120 gallons of Category 4 flammable liquids shall be stored in any one storage cabinet.” Additionally, no more than three such cabinets may be located in a single storage area. All chemical storage cabinets must be labeled with the phrase, “Flammable-Keep Away from Open Flames.” Each letter height for “FLAMMABLE” should be two inches while the minimum letter height for “KEEP FIRE AWAY” should be one inch.

Do I Need Ventilation?

The NFPA 30 stresses the importance of proper ventilation in preventing the accumulation of toxic vapors and gases inside your hazardous material storage area. Portable tanks not exceeding 660 gallons must have emergency venting in accordance with chapters II and III of the The Flammable and Combustible Liquids Code, NFPA 30-1969. Mechanical ventilation can reduce the toxic accumulation of deadly vapors by performing six air changers per hour.