Hazardous materials storage is the compliant protection of dangerous and toxic chemicals. Chemical storage can be as small as a wooden cabinet or as large as a Conex box. While many hazardous materials are necessary for industrial production, they also pose health, safety, and environmental threats. Hazardous materials can exist in a solid, semi-solid, gas, or liquid. Chemical reactions can also cause transformations to and from various states. OSHA and the National Fire Protection Association classify chemicals according to their known hazards and volatility. Compliant hazardous materials storage mitigates health, safety, and environmental threats while allowing for easy storage and removal of dangerous substances.

What are Some Common Hazardous Materials?

Common examples of hazardous materials include ethanol, pesticides, fertilizers, petroleum, gasoline, lithium-ion and solid-state batteries, toxic drugs, disinfectants, stripping agents, paint, chlorine, and peroxide. OSHA compliant protection of each chemical is determined by flammability and health and safety risks.

What is Compliant Hazardous Materials Storage?

Following the suggested storage practices of the NFPA, OSHA routinely enforces thousands of hazardous materials regulations. OSHA allows for the wooden and steel construction of hazardous materials cabinets and storage lockers. All steel constructed hazmat lockers require 18-gauge steel sheet protection and a three-latch door arrangement. Hazardous materials must never be stored next to incompatible materials of another hazardous classification. For example, ethanol should never be stored with peroxides and metals, as these chemicals can cause an adverse chemical reaction with the host substance.

Can Hazardous Materials Be Stored in a Regular Warehouse?

No. Traditional warehouses cannot be used to store hazardous materials because they are not outfitted with fire and spill mitigation safety features. Certain certification processes are necessary for sanctioned chemical storage in warehouses.

Can Different Hazardous Materials be Stored Together in Same Storage Locker?

Differing classes of hazardous materials can only be stored together if stored separately in clearly designated and marked areas. Never store hazardous materials with incompatible materials.

What Are Acceptable Quantities for a Single Storage Locker?

OSHA allows for the storage of 25 gallons of flammable liquid outside a compliant storage container. Additionally, OSHA requires no more than 60 gallons of flammable liquid (flashpoint below 140 degrees F) or 120 gallons of combustible (flashpoint at or above 140 degrees F) can be stored in a single chemical storage container or warehouse. OSHA also requires rated storage safety cabinets when possible. Furthermore, any Category I, II, or III flammable liquids should be kept in closed containers when not in use. Flammable materials should never be stored in areas used for exits, stairways, or egresses. Additionally, flammable materials should always be stored at or below eye level. Avoid stacking flammable materials and never store these chemicals with incompatible hazardous materials.

How are Large Volumes of Hazardous Materials Stored?

Hazardous material stockpiles greater than 25 gallons should be stored in chemical drums or IBC tote system. An IBC container is an industrial grade container commonly used for storing and transporting large quantities of liquids, solids, and semi solids. They are reusable and cost-efficient. Furthermore, IBC containers can be palletized, allowing for their easy storage and removal. IBC totes are commonly made of metal, plastic, or composite material. Metal drums and IBC totes should be stored in a hazardous materials storage locker by hand truck or forklift.

How Does Hazardous Materials Storage Differ From Traditional Storage?

Hazardous materials require superior protection not afforded to other jobsite tools and equipment. You should avoid storing hazardous materials with other tools of the trade. Larger hazardous chemicals inventory necessitate congruent steel fortification with spatial considerations. While some larger hazardous materials storage lockers resemble common Connex storage containers, they differ in safety features and application. Most flammable chemical inventories require superior steel welds, explosion relief panels, ventilation, and climate protection. Spill sump containment is commonly attached to the bottom of large chemical storage units to prevent leaks from polluting and contaminating the ecosystem.

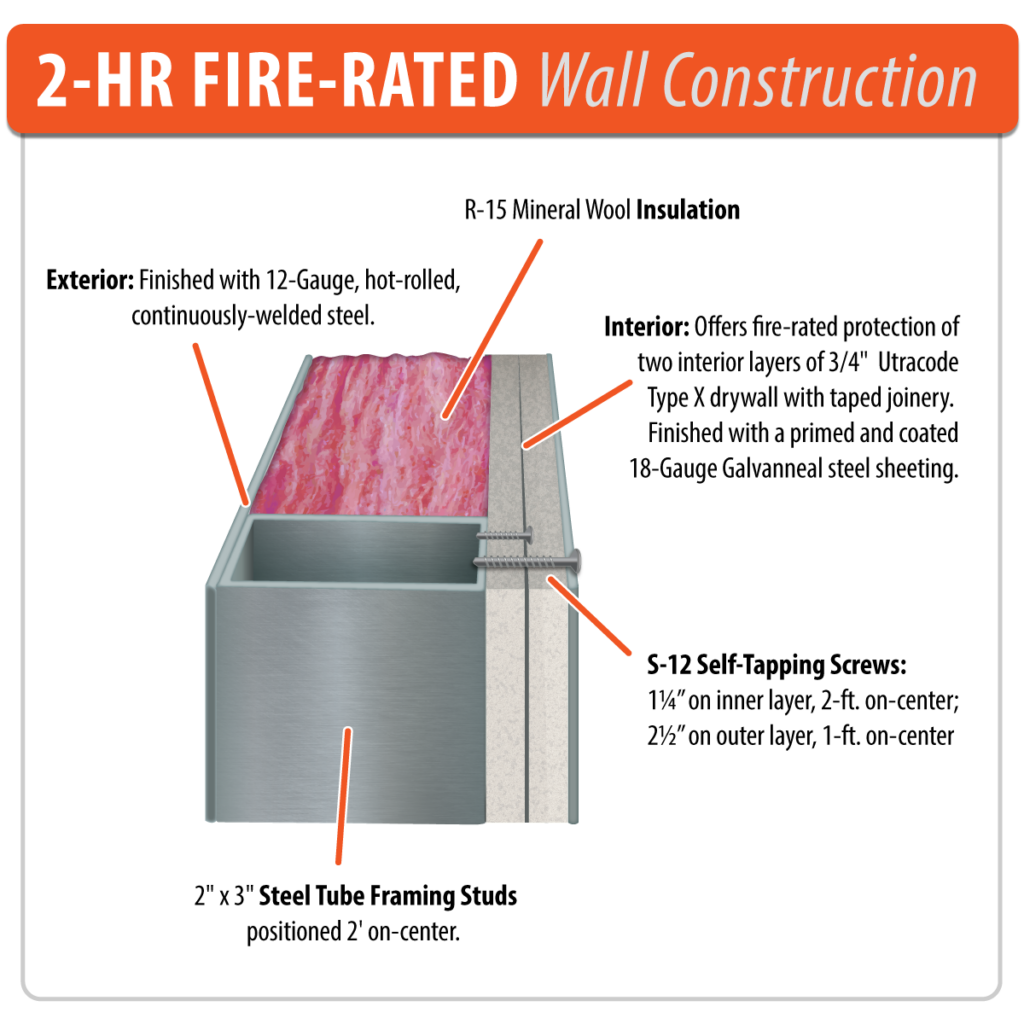

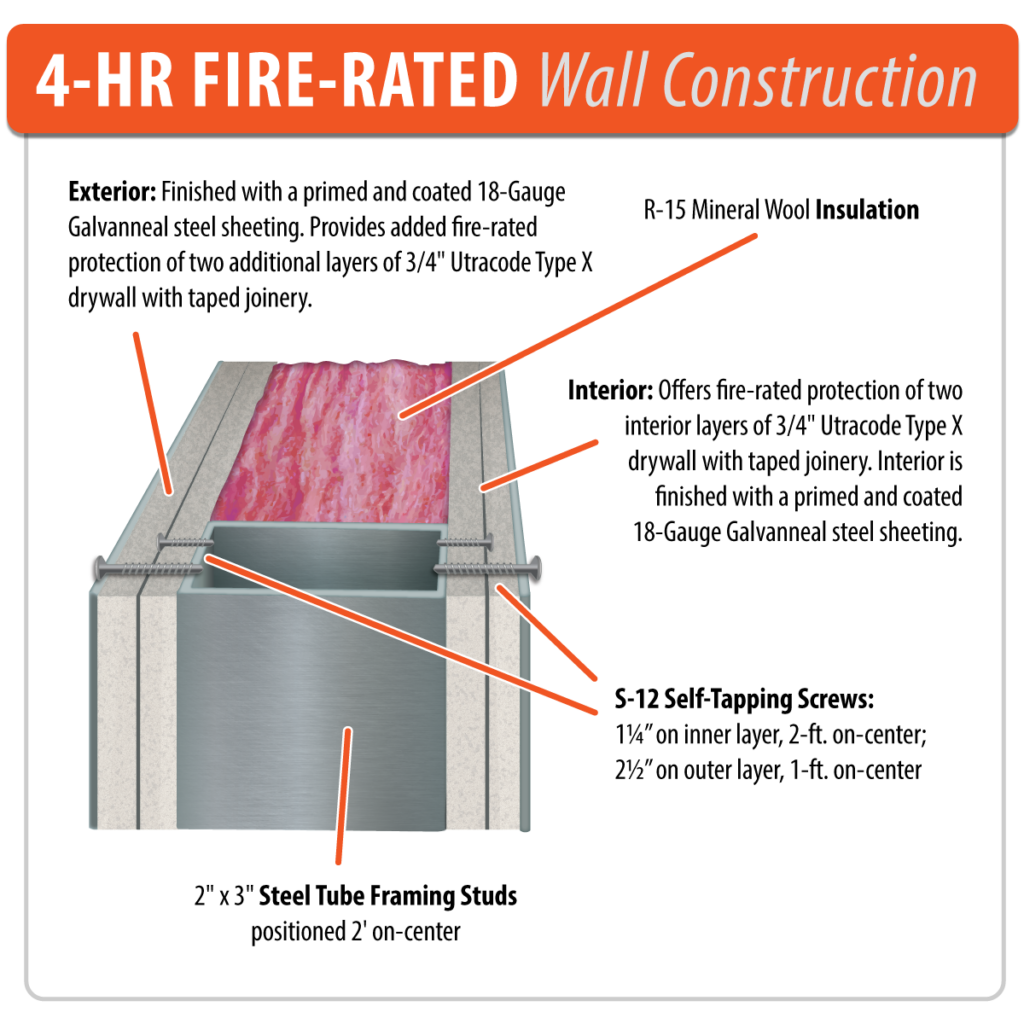

What’s the Difference Between Fire-Rated and Non Fire-Rated Chemical Storage?

Chemical storage lockers are broken down between fire-rated and non-fire rated options. Fire-rated chemical storage is necessary for flammable liquids and solids. These storage lockers have insulated fire panels, comprised of fire-resistant materials and optional explosion relief panels to minimize potential blasts radiuses. Our fire-rated storage buildings come in two and four-hour fire protection. For example, a storage cabinet with two hours of listed protection means the stored chemicals will be protected from the fire for two hours.

What Happens if I Ignore OSHA Hazardous Materials Storage Regulations?

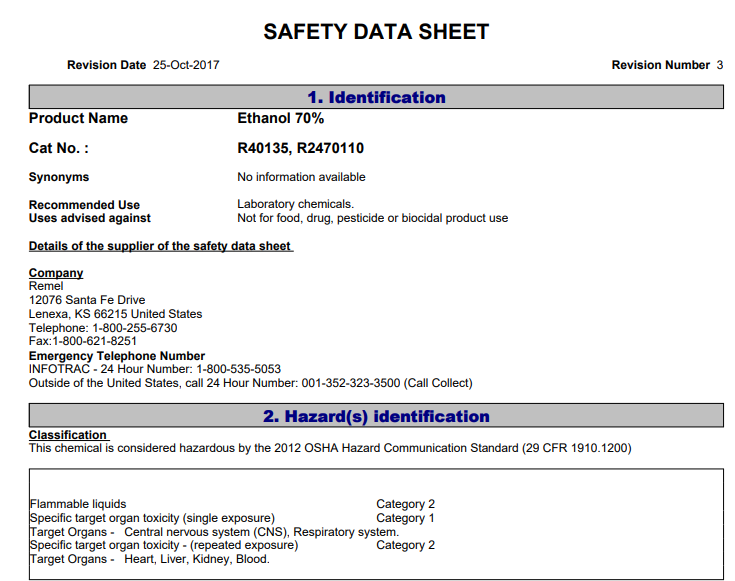

Failure to abide by OSHA Hazardous Materials Storage Regulations can result in hefty civil penalties and loss of operators’ licenses. Improper storage of hazardous materials is a leading cause of industrial fires, spills, and accidents. Because OSHA inspectors routinely inspect chemical storage facilities, it is important to stay abreast of changing hazardous materials regulations. All employees should also receive standard training for the handling and storage of hazardous materials found on your jobsite. Material Safety Data Sheets should be readily available for all industry employees.

What is a Material Safety Data Sheet?

A material safety data sheet provides unique physical properties and known risks for each hazardous chemical. A MSDS for one chemical will differ entirely from another product’s MSDS. For example, a MSDS for ethanol is separate and unique from a propane safety data sheet. Moreover, a MSDS provides concise details of each relevant hazardous chemical, including chemical properties, a list of incompatible materials, known hazards, flash and boiling points, first aid measures, and general storage guidelines.

Can I Rent a Chemical Storage Locker?

Not every job requires a permanent steel solution. Although certain industrial facilities need continuous hazardous materials protection, other transient industries, including construction and the oil industry, only require temporary storage depending upon jobsite requirements. Renting hazardous materials storage is also more cost-effective and convenient. We can provide temporary solutions to short-term storage dilemmas. Contact us today for a free quote and consultation.